FM310 Edgebander

The FM310 Edgebander is a compact and sturdy single-side edge banding machine, ideal for both industrial and artisan use. It features a quick-heating glue pot and is capable of applying PVC, ABS, melamine, veneer, and solid wood edges. The units are adjusted with a pressure bar equipped with a double row of wheels, ensuring precise and efficient operation.

- Crafted with precision

Product Features

Control Panel

The management of the machine and its working units is performed by an electronic control PLC. On the screen the following data are displayed: feed rate, glue tank temperature, program type selected by the operator, integrated simple and controlled diagnostic.

- Crafted with precision

Product Features

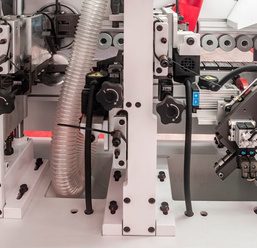

Heavy Duty Trimming Unit

The stable frame design is adopted to reduce the instability of trimming quality caused by the jitter of the tool during high speed cutting.

- Crafted with precision

Product Features

End Trimming Unit

Adopt air pressure balance device to make the head more stable and easy to adjust. The pneumatic design is optimized to reduce the noise and improve the efficiency of the cutting equipment.

- Innovation. Automation. Satisfaction.

Design Features

With all Farnese machines, we pride ourselves on making features simple to use. Our commitment to intuitive design ensures ease of operation and minimal training requirements.

Machine structure in ribbed electrically welded steel, to grant high rigidity.

The machine has a compact design, is versatile and user friendly.

Extensible panel support with roller for large-sized panels.

All working units are protected by a cabin with wide opening allowing excellent view of the inner parts.

All motors turn at 12,000 rpm and are controlled by an inverter of suitable power according to machine configuration.